Cross-industry Applications for Packaging

UGI proves its innovative features and well-engineered strengths of cross-industry applications for packaging boxes and bags. With its flexible and open production process it can easily and safely adapt to different requirements of your packaging creation - Our solutions for packaging requirements in one specific sector can also be of use in other sectors and industries.

Our commitment to innovation can be seen in all aspects of our customers' value chain, from brand development to filling and retail display. It is this proposition that positions us as a business partner and not just a supplier.

Innovations

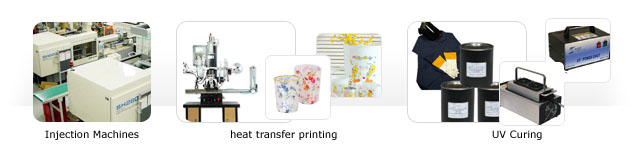

New technology continues to pose new challenges to the packaging manufacturer. For example, UV curing rapidly becoming the technique of choice for coatings in the packaging industry, but it's not been all plain sailing.

Complex part shapes, temperature sensitive substrates and demanding finish quality are just some of the challenges faced by packaging manufacturer, plastic injection and thermal (water) transfer printing manufacturers alike.

Our product is always complimentary to others so we must form the right relationships with interrelated suppliers from which all parties can benefit. In understanding the industry's future requirements, we give our customers added advantage as we continue to offer the best to our chosen markets.

Showcase: Plastic Watch Winder with Wooden Grain

- Integration from our plastic injection molding, heat transfer printing, and UV curing

Our specially designed compact automatic watch winder box will keep your favorite automatic watches wound and ready for when you need them.

Material:

Plastic structure (HIPS, ABS)

The plastic build has much lower cost than solid wood or MDF construction.

The interior is lined with smooth cream faux leather to protect your watches.

Printing: Heat transfer with wood grain

Its wooden exterior has mahogany wooden grain finish and see-through side and top windows to show your timepieces.

Surface Treatment: UV curing

High glossy UV curing surface finish allows we to make the watch winders more attractive and durable from scratch and color fade.

Engineering System: silent motor

A silent motor keeps the watches moving on turntable.

This watch winder will rotate clockwise, auto swap or counter-clockwise which will meet most automatic watch requirements and has gorgeous appearance as traditional wooden watch boxes but only half costs comparing with the wooden boxes.

The reasons for our success!

Our multidisciplinary, cross-functional project teams help you to conceptualize, design, test, manufacture, launch and screen your new products. Ideas are generated from a variety of sources, including inventors, employees and customers. We use a proven discovery approach to ensure that the right ideas come through. This includes a thorough analysis of the external environment, an internal core competencies assessment, the development of alternative future scenarios and a close look at customer and consumer research. New ideas pass through a five-part process, starting with idea generation and finishing with product launch and approval.

Quality

At UGI, the philosophy of Quality is understood and adopted by the whole Company. Quality Control remains part of what we do as a manufacturer, but Quality Assurance throughout manufacture, means we continue to constantly strive for improved procedures.

Customers support

UGI is able to offer customers a complete special package around the cross-industry application for packaging demands. Our Technical Service Team offers support on a range of issues from colour matching to complex problem solving by way of short term development. On a global scale, UGI is active on all continents. We pride ourselves in the technical ability of our sales people, who can be relied upon for fast and accurate advice, backed by a responsive technical presence.

Environmental issues

The commitment of UGI means much more than only producing quality products. We take seriously our responsibility to the environment. We openly publish our intent and policies on this issue and are regularly audited by impartial bodies to ensure our continued improvements in this issue.

UGI Packaging's Quality Policy

UGI Packaging is committed to being an effective, efficient & competitive organization by focusing on:

-

Identifying, planning and meeting customer satisfaction requirements.

-

Supplying Product and services to customer specified requirements in the most cost effective, safe, and environmentally conscious manner.

-

The review of our management system suitability, objectives, and targets to promote improvement and balance in quality, delivery, cost, profitability, and customer satisfaction.

-

Environmental protection through pollution prevention and resource consumption management.

-

Compliance to relevant and subscribed governing laws, regulations, technical specification requirements.

-

Promoting awareness of our Quality Management objectives and environmental stewardship with our employees and community.

More new product development pls visit:

Thermal(water) transfer printing

UV curing paint

Plastic injection molded packaging

Call us today on + (86) 135 333 11702 or email us [email protected] - We can create a fully animated working model to show how your pack will make up, and we'll gladly guarantee that you will receive the best product with great satisfaction at a best price!