The Importance of Collapsible Rigid Boxes in the Fashion Industry

In the fashion industry, packaging plays a crucial role in the marketing and promotion of products. One type of packaging that has gained popularity in recent years is the collapsible rigid box. This type of box is made of rigid materials, such as paperboard or plastic, and is designed to be collapsible, making it easy to store and transport. Please click here to view our Graphic Design, Printing & Packaging Box showcases, and discuss with our engineers to customize your next printing and gift packaging!

Why Collapsible Rigid Boxes are Ideal for the Fashion Industry

Collapsible rigid boxes are particularly well-suited for the fashion industry for several reasons:

- Luxury Feel: Collapsible rigid boxes have a luxurious feel that is perfect for high-end fashion brands. They are made of high-quality materials and have a sturdy construction that gives them a premium look and feel.

- Customization: Collapsible rigid boxes can be customized to fit the specific needs of fashion brands. They can be printed with logos, patterns, and designs that match the brand’s aesthetic, making them a great way to promote the brand and create a cohesive look.

- Protection: Collapsible rigid boxes provide excellent protection for clothing and accessories during shipping and storage. They are designed to keep items safe from damage and creasing, which is especially important for delicate or high-value items.

- Convenience: Collapsible rigid boxes are easy to use and convenient for customers. They can be easily opened and closed, and they provide a secure way to store and transport clothing and accessories.

How Collapsible Rigid Boxes Can Help Fashion Brands Save Money

Collapsible rigid boxes can help fashion brands save money in several ways:

- Reduced Shipping Costs: Collapsible rigid boxes are designed to be compact and lightweight, which makes them cheaper to ship. This can help fashion brands save money on shipping costs, which can be a significant expense.

- Reduced Storage Costs: Collapsible rigid boxes are also designed to be space-efficient, which means they take up less room in storage. This can help fashion brands save money on storage costs, which can be a significant expense, especially for brands with large inventory.

- Increased Efficiency: Collapsible rigid boxes can also help fashion brands increase efficiency by reducing the time and labor required to package and ship products. This can help brands save money on labor costs and improve their overall productivity.

Design, Materials, and Manufacturing Process

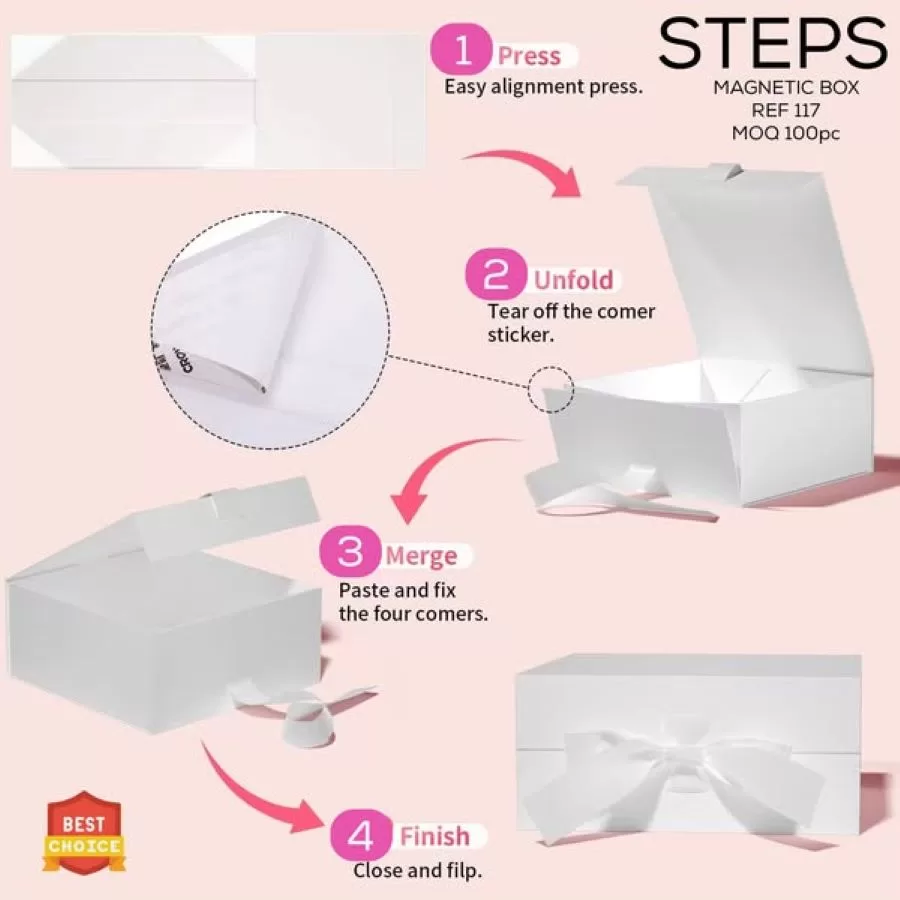

Collapsible rigid boxes are made of a variety of materials, including paperboard, plastic, and foam. The design and manufacturing process typically involves the following steps:

- Design: The design process typically begins with a concept or idea. The designer will create a prototype of the box, taking into account the size, shape, and material requirements.

- Material Selection: The next step is to select the materials for the box. This will depend on the desired look and feel of the box, as well as the budget and sustainability requirements.

- Manufacturing: The manufacturing process typically involves cutting, creasing, and folding the materials to create the box shape. The box is then printed and finished with any additional coatings or treatments.

- Quality Control: The final step is quality control, where the boxes are inspected for defects and irregularities.

Equipment and Machinery

The equipment and machinery used to manufacture collapsible rigid boxes vary depending on the material and design requirements. Some common equipment and machinery used in the manufacturing process include:

- Die-cutting machines: These machines are used to cut out the box shape from the material.

- Creasing machines: These machines are used to create the creases and folds in the box.

- Folding machines: These machines are used to fold the box into its final shape.

- Printing machines: These machines are used to print the box with logos, patterns, and designs.

Contact us right now!

Collapsible rigid boxes are a popular packaging solution for the fashion industry due to their luxurious feel, customization options, protection, and convenience. They can help fashion brands save money on shipping and storage costs, while also increasing efficiency and productivity. The design, materials, and manufacturing process of collapsible rigid boxes require careful consideration to ensure that the final product meets the desired look and feel of the brand.

Interested in exploring the application of these custom design & surface treatment processes in printing & packaging products? Click here to access our online showcases & guides…

Here at UGI, we design and manufacture various boxes for many industries:

Advertising boxes; bakery boxes; bottle boxes; candies boxes; cardboard boxes; drawer boxes; cigarettes boxes; file storages boxes; heart shaped boxes; medicine packaging; moving boxes; packaging gift boxes; paperboard packaging; product boxes; protective packaging; retail boxes; shipping cartons; napkin boxes; chipboard boxes; fruit vegetable boxes; electronic packaging boxes; card boxes; craft boxes; lunch boxes; display boxes; folding boxes; clear boxes; mailing boxes; chocolate boxes; cloth boxes; cake boxes; candle boxes; and as well as many others…

WORKING PROCESS

In order to get a smooth process to fulfill your order we suggest you follow below working process with UGI Packaging:

- Request a quote based on the specifications you require via email. Include any photos, images, art design, or technical sketch that could be helpful.

- If you have a similar or identical box to that which you require, send it (via UPS, TNT, DHL, or FEDEX) only after you are satisfied with our quote has been received.

- UGI Packaging will then provide you with a sample and a final quote with our technical sketch in PDF, AI, or CDR format. We will charge you for the sample or prototype development, but it should only be a nominal amounts. After receive your formal order, we will refund the sample charge as our negotiation.

- If you approve the sample then place your order and sign the contract, with 40% advance payment from you, we will start production.

- If any significant changes need to be made to the sample we strongly recommend checking 2nd samples from us before you confirm the final version.

Connect with us on WhatsApp to discuss your next packaging design solution with our manufacturing!